Introduction to Coal and Mineral Testing

Coal and mineral testing is a critical process employed in the mining and resource extraction industries. It serves to assess the quality, composition, and overall characteristics of the materials being mined. The significance of testing lies in its ability to determine the value of these resources, which impacts economic viability, efficiency in processing, and compliance with environmental regulations.

The testing processes typically involve various analytical techniques designed to analyze samples of coal and minerals. These techniques may include proximate analysis for moisture and volatile matter content, ultimate analysis for elemental composition, and calorific value testing to assess energy content. Additionally, mineralogical analysis is conducted to identify the specific minerals present in a sample, which is essential for understanding the behavior and applications of the material.

Various types of coal, such as anthracite, bituminous, sub-bituminous, and lignite, are commonly subjected to testing due to their differing energy outputs and applications. Similarly, minerals such as iron ore, copper, gold, and bauxite are tested to evaluate their quality and suitability for various processes in metallurgy and production of goods. Understanding the properties of these materials through rigorous testing is vital for making informed decisions about their extraction and industrial usage.

In essence, coal and mineral testing provides vital information that influences the strategic planning and operational efficiency of mining projects. By employing precise testing methods, companies can optimize resource utilization while ensuring compliance with industry standards, thereby enhancing profitability and sustainability in resource extraction.

The Importance of Accurate Testing in Resource Management

Accurate testing in coal and mineral analysis is essential for effective resource management. The reliability of test results directly influences decision-making processes related to resource extraction, the assessment of environmental impacts, and adherence to regulatory standards. Precise data derived from testing provides stakeholders with critical insights into the composition and quality of geological resources. These insights are pivotal for planning extraction strategies that maximize efficiency while minimizing waste and environmental disruption.

For instance, when companies have exact information regarding the mineral content in a given deposit, they can optimize their extraction methods to ensure they are utilizing the most effective techniques. This not only facilitates higher yield rates but also conserves natural resources. Informing extraction operations with precise testing becomes even more significant in an era where sustainability and environmental protections are paramount concerns. Environmental impact assessments rely heavily on accurate data to predict potential damage from mining activities, influencing permitting processes and community relations.

Moreover, compliance with governmental regulations is rigorous in the mineral extraction industry. Accurate testing data serves as a basis for demonstrating compliance with environmental laws and regulations. Regulatory agencies often require detailed reports based on test results to assess potential impacts on ecosystems and to enforce sustainability practices throughout the extraction process.

In conclusion, the role of precise testing in resource management cannot be understated. It provides a foundation for efficient and sustainable practices within the coal and mineral sectors, ensuring that extraction processes are not only economically viable but also environmentally responsible.

Factors Influencing Testing Costs

Understanding the costs associated with coal and mineral testing is essential for stakeholders in the industry. Numerous factors can affect these costs, impacting on both the overall budget and the accuracy of results achieved. One primary factor is the equipment used during testing. Advanced and more sophisticated instruments often incur higher operational costs due to maintenance and calibration requirements. Conversely, the utilization of older or basic equipment may reduce testing prices, but potentially compromise the accuracy of results.

Another significant contributor to testing expenses is the laboratory fees. Different laboratories may have varying pricing structures based on their expertise, accreditation, and the quality of service they provide. Moreover, comprehensively accredited labs that comply with international standards may charge more, reflecting their established reputation within the industry.

The sample size also plays a vital role in determining testing costs. Larger sample sizes typically require more resources and time to analyze, leading to increased fees. In contrast, smaller samples may not adequately represent a bulk material, potentially affecting the reliability of the findings. Therefore, optimizing sample size is a critical consideration when planning coal and mineral testing.

Additionally, the transportation costs involved in sending samples to testing facilities can contribute significantly to the overall expenses. These costs can vary based on the distance from the collection site to the laboratory and the method of transportation employed.

Lastly, the type of analysis performed must be considered, as different analyses may demand various levels of technical expertise or specialized reagents, further impacting costs. Understanding these factors is crucial for stakeholders looking for accurate and cost-effective testing solutions in the coal and mineral sector.

Understanding Turnaround Time in Testing

Turnaround time (TAT) in the context of coal and mineral testing refers to the duration it takes from the receipt of a sample to the delivery of the test results. This timeframe is crucial as it influences decision-making processes for businesses in various sectors, including mining, energy, and manufacturing. The complexity of the testing procedure is one of the primary factors that determine turnaround time. Different tests require varying degrees of sophistication and analysis, which can significantly impact how quickly results are generated.

Moreover, laboratory capacities play a critical role in defining the turnaround time. Laboratories may have different levels of staffing, equipment availability, and technological advancements, all of which contribute to the efficiency of processing samples. A well-equipped laboratory with a streamlined process is likely to deliver results faster than one that lacks the necessary resources or has a backlog of samples awaiting analysis.

In addition, the priority assigned to tests by clients can further influence turnaround times. Certain industries, especially those that are time-sensitive, may request expedited services, placing them at the forefront of the testing queue. Laboratories often accommodate these requests; however, clients should be aware that prioritization may come with additional costs or the need for more rigorous scheduling.

Ultimately, understanding the factors that affect turnaround time is essential for clients seeking timely and accurate results from coal and mineral testing. By considering the complexity of tests, laboratory capacities, and the urgency of their needs, clients can better navigate the processes involved and make informed choices regarding their testing requirements.

Balancing Cost and Accuracy in Testing Services

In the realm of coal and mineral testing, striking a balance between cost and accuracy is crucial for stakeholders in the mining and resource extraction industries. Testing services often present a variety of options that differ in price, leading clients to question how these costs relate to the reliability and precision of the results they provide.

It is essential to understand that while lower-cost testing services may seem financially appealing, they can potentially compromise the accuracy of the test results. Testing accuracy is paramount, as it directly influences operational decisions, compliance with regulatory standards, and the overall integrity of resource management. Consequently, clients must weigh short-term savings against the long-term implications of less accurate results.

One must consider that more expensive testing services typically invest in advanced technology, highly trained personnel, and rigorous quality control measures. Such investments often lead to higher precision in test results, thus mitigating risks associated with incorrect or misleading data. Conversely, lower-cost alternatives may rely on less sophisticated methodologies or equipment, increasing the likelihood of inaccuracies that could adversely affect operational outcomes.

When selecting testing services, clients should focus not only on the price tag but also on the provider’s reputation and track record in delivering reliable results. Engaging with testing laboratories that demonstrate a commitment to quality and accuracy can ultimately result in better data for decision-making, thus tending to outweigh the initial cost savings.

In essence, the interplay between cost and accuracy in coal and mineral testing is complex. Clients need to conduct thorough research and understand the importance of investing in accurate testing services, ultimately supporting their business operations and ensuring compliance with industry standards.

Advanced Technologies in Coal and Mineral Testing

The field of coal and mineral testing has witnessed remarkable advancements in recent years, thanks to the continuous integration of cutting-edge technologies. These innovations have significantly enhanced the accuracy, efficiency, and cost-effectiveness of testing processes. One notable advancement is the adoption of high-resolution imaging techniques, which allow for detailed analysis of mineral samples. This technology enables geologists and mineralogists to uncover essential characteristics that might be overlooked through traditional methods.

Another key development is the implementation of automated sampling and analytical systems. These systems not only streamline the testing process but also minimize human error, ensuring that results are more reliable. Automated systems utilize sophisticated algorithms to analyze data quickly, thereby reducing turnaround times for test results. This is especially important in industries where timing can affect financial decisions and operational efficiency.

Additionally, advancements in spectroscopy techniques, such as X-ray fluorescence (XRF) and laser-induced breakdown spectroscopy (LIBS), have transformed the way elements and compounds in coal and mineral samples are identified and quantified. These methods provide rapid and precise analyses, aligning perfectly with the industry’s need for speed and accuracy.

The incorporation of artificial intelligence (AI) into testing procedures further enhances performance by allowing for predictive modeling and data analysis. AI can identify patterns and provide insights that improve decision-making processes for mining and resource exploration. These technologies collectively push the boundaries of traditional coal and mineral testing, offering the potential for greater accuracy, reduced turnaround times, and lower overall testing costs.

Case Studies: Cost, Time, and Accuracy in Action

To understand how cost, turnaround time, and accuracy in coal and mineral testing substantially influence decision-making and operational effectiveness, it is beneficial to examine specific case studies that showcase these factors in a real-world context.

One notable case occurred within a large mining company located in Australia, where they sought to optimize their operations and reduce costs. The company faced delays due to inaccurate assay results that required retesting and thus prolonged their production schedule. By implementing a more efficient testing protocol, they not only cut costs by 15% but also reduced turnaround time by 30%, allowing them to deliver products faster to market.

In another instance, a medium-sized mineral exploration company in Canada was contemplating a major investment in a new mining project. They required highly accurate mineral composition analysis to ensure that their investment was well-founded. By utilizing advanced testing technologies, they obtained results that had an accuracy rate above 98%. This confidence in data allowed them to move forward with the project, which ultimately led to a significant increase in their operational efficiency and profitability.

Furthermore, a testing laboratory in South Africa worked closely with various mining operations to improve their analytical processes. They introduced a rapid testing service that dramatically decreased turnaround time without compromising accuracy. This innovation not only helped clients reduce downtime but also saved on operational costs, positioning the lab as a leader in the industry.

These case studies illustrate the critical interplay between cost, turnaround time, and accuracy in coal and mineral testing, emphasizing how each element can significantly affect strategic decision-making within the mining sector. By investing in high-quality testing services, companies can achieve considerable advantages that translate into enhanced productivity and profitability.

Regulatory Compliance and Testing Standards

In the realm of coal and mineral testing, adherence to regulatory compliance and established testing standards plays a pivotal role. Regulatory bodies set forth guidelines and protocols that ensure testing is performed accurately, consistently, and ethically. These standards are designed to protect environmental health and safety, while also ensuring that the results obtained from testing are reliable. Non-compliance with these regulations can lead to significant legal repercussions, financial penalties, and damage to reputation.

The influence of compliance on costs cannot be overstated. Laboratories that adhere strictly to regulatory requirements may incur higher operational costs due to the need for advanced equipment, rigorous training of personnel, and comprehensive quality management systems. However, these costs are often justified by the benefits of obtaining accurate test results that meet the necessary regulatory standards. Accurate testing also helps organizations in making informed decisions regarding resource management, thereby potentially saving costs in future operations.

Turnaround times in coal and mineral testing are also affected by regulatory compliance. Laboratories must ensure tests are performed in accordance with the stipulated guidelines, which can introduce additional time requirements for processes such as sample preparation, analysis, and quality assurance. While a more extensive testing process may increase turnaround times, it is essential for ensuring that the results are credible and meet strict industry standards.

Lastly, accuracy in test results is inherently linked to compliance with testing standards. Regulatory frameworks are developed based on extensive research and industry best practices, which contribute to the validity of the testing procedures employed. Therefore, maintaining compliance is crucial for achieving high levels of accuracy in coal and mineral testing results, ultimately safeguarding the interests of all stakeholders involved.

Conclusion: Making Informed Decisions for Testing Needs

In the field of coal and mineral testing, stakeholders often face the critical challenge of balancing cost, turnaround time, and accuracy. Each of these factors plays a vital role in the decision-making process.

Firstly, it is essential for organizations to assess their specific testing requirements meticulously. Cost considerations should not lead to sacrificing the integrity of the testing process; therefore, selecting laboratories that provide transparent pricing alongside high-quality services is imperative. Evaluating the overall value rather than just the cost can result in more beneficial outcomes.

Secondly, turnaround time is an ever-increasing demand in today’s fast-paced industry. Prompt testing can significantly impact operational timelines and decision-making processes. Consequently, stakeholders should prioritize testing options that offer reliable yet expedited services, ensuring that both speed and accuracy are maintained without compromising the results.

Moreover, accuracy cannot be overstated in testing outcomes, particularly in industries where decisions based on data can have significant implications. It is advisable for stakeholders to select established laboratories that utilize advanced testing methodologies and adhere to stringent quality control measures. This step ensures that the results are not only timely but also trustworthy.

Incorporating these strategic considerations cost assessments, turnaround time expectations, and accuracy requirements will equip stakeholders to make informed decisions tailored to their specific needs. By engaging with certified laboratories that align with these priorities, organizations can achieve optimal testing outcomes that advance their operational goals. Ultimately, understanding the nuanced relationship between these three critical factors will facilitate better resource allocation and enhance overall project success in the coal and mineral sectors.

Source: https://darshlabsandresearch.com/coal-&-minerals-testing/understanding-cost-turnaround-time-and-accuracy-in-coal-and-mineral-testing

Bengaluru, Jan 07: The Sadguru Sri Thyagabrahma Aradhana Kainkarya Trust is organizing the 179th Vaidika Aradhana of the poet-saint Sri Thyagaraja from January 7 to January 11, 2026, at the Sringeri Shankara Matha, Chamarajapete, Bengaluru.

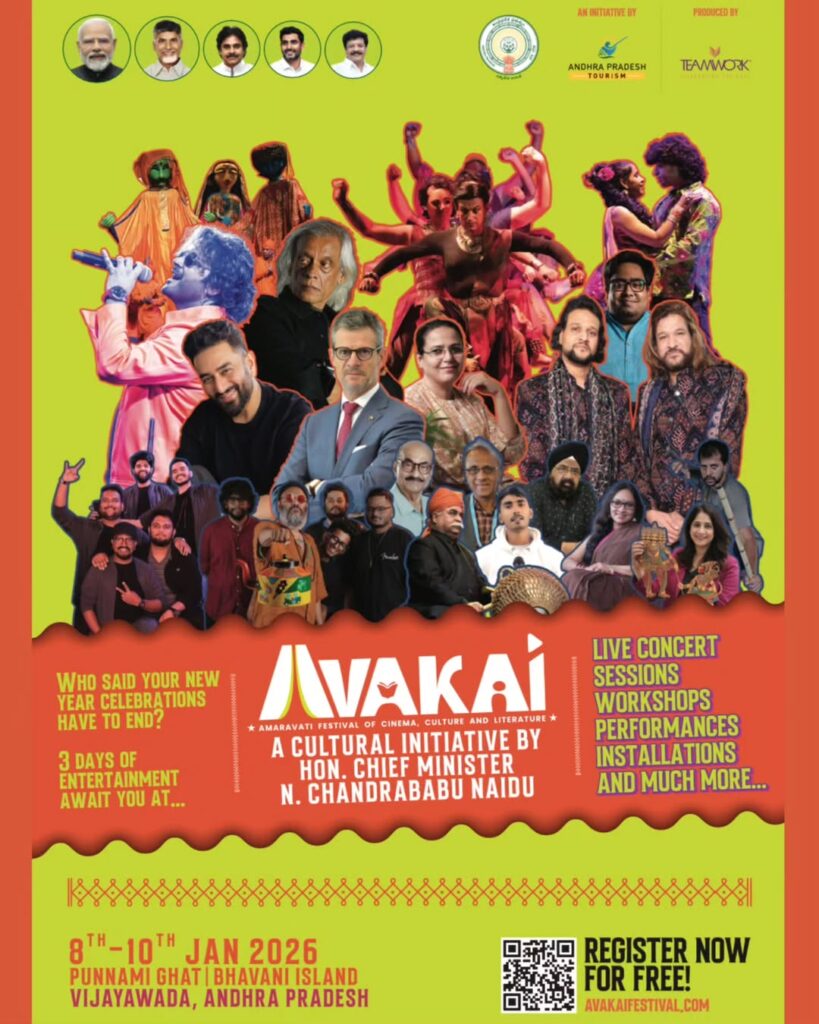

Bengaluru, Jan 07: The Sadguru Sri Thyagabrahma Aradhana Kainkarya Trust is organizing the 179th Vaidika Aradhana of the poet-saint Sri Thyagaraja from January 7 to January 11, 2026, at the Sringeri Shankara Matha, Chamarajapete, Bengaluru. Vijayawada, Jan 07: The Government of Andhra Pradesh presents Avakai: Amaravati Festival of Cinema, Culture and Literature, a three-day public cultural celebration to be held from 8th to 10th January 2026 at Punnami Ghat and Bhavani Island, Vijayawada. Conceived as an open, inclusive riverfront festival, Avakai brings cinema, literature and the performing arts into public spaces, creating direct engagement between artists and audiences, while transforming the banks of the River Krishna into a vibrant site of cultural exchange and creative dialogue.

Vijayawada, Jan 07: The Government of Andhra Pradesh presents Avakai: Amaravati Festival of Cinema, Culture and Literature, a three-day public cultural celebration to be held from 8th to 10th January 2026 at Punnami Ghat and Bhavani Island, Vijayawada. Conceived as an open, inclusive riverfront festival, Avakai brings cinema, literature and the performing arts into public spaces, creating direct engagement between artists and audiences, while transforming the banks of the River Krishna into a vibrant site of cultural exchange and creative dialogue.

Mumbai, Jan 06: The Indian Hotels Company Limited (

Mumbai, Jan 06: The Indian Hotels Company Limited (